Written by Pat Hagan, Director of Safety LPR/Longbow

LPR Construction is proud to announce our achievement in Total Recordable Incident Rate Reduction for yearend 2017. We completed the year with a TRIR of 0.38. Although we realize that recordable rates are a “Lagging” indicator, we believe our success is deeply rooted in our LPR Core Values. The elements of which drive our process, methodology and who we are as a company. Our commitment to ensure everything we do protects our employees, customers and the public is always in the forefront.

How those Core Values relate to our reduction in the recordable rate can best be explained by reviewing each value:

Committ ed to Safety

ed to Safety

• Our commitment to safety starts at the top with our Executive Management Team. They are engaged in every step of creating, socializing, implementing and evaluating our process. They drive participation from job site audits, incident reviews, project/supervisor training, to our craft listening tour. This is the example that is set every day for our work force.

We Over Me

• The word “I” is not in our vocabulary. Everything we do from education for our craft on hazards associated with their work, to detailing safe steps in the work processes that drive our business, is a Team Effort.

Competitive Sprit

• We apply this in how we approach our business regarding finding ways to better the safety of our craft and staff. We never settle for the status quo, but rather always search out better ways to protect our most valuable asset…Our Employees!

Do What You Say

• We tell our craft and staff that we are “committed to their safety, and want them to go home the same way they showed up”. Although that may sound cliché, we apply that to the development of all processes, programs, training, etc. I order to better protect the employees of LPR.

Be Part of the Solution

• We engage our craft to participate in all aspects of safety, from driving the responsibility to “never walk by a hazard” to performing audits and job site safety briefings. We value input from all of our employees, making adjustments for improvement.

Driven to Learn and Share Knowledge

• This is where the ‘rubber meets the road’ for eliminating hazards that injure employees. We are constantly researching new ideas for safety training, equipment, methods, etc. and leveraging technology to apply it to our business. Our founder invented a fall protection device for steel erection that has become the industry standard in protecting workers from falls!

So, when people say “TRIR is a Lagging Indicator” I just point to the Core Values that drive our business every day!

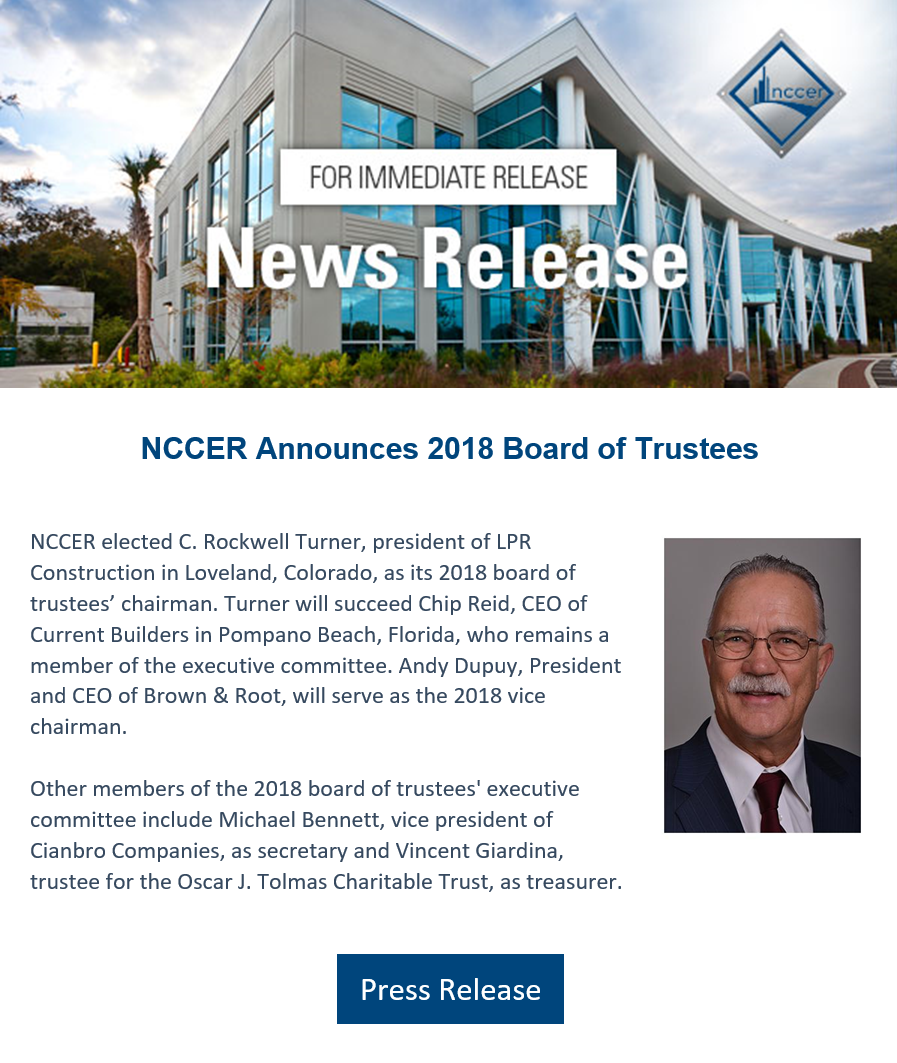

PR and Longbow Industries are proud to boast that our CEO, Rocky Turner, has been appointed Chairman of the 2018 Board of NCCER Trustees. LPR’s continued commitment to a cutting-edge apprentice program for our ironworkers, as well as other trades, facilitates our continued commitment to being both an NCCER Assessment Center and a Training Center. Currently we have apprentices in all levels of the program and assigned mentors, journeyman and above, to answer their content questions, serve as proctors and instructors, and provide the hands-on site-based training we know is most effective for our craft workers. Looking to partner closely with local high schools, Front Range Community College and other community programs supporting the craft trades, we hope to develop a ‘grow our own’ program utilizing a strong NCCER curriculum, coupled with training provided by some of the most skilled ironworkers in the industry.

PR and Longbow Industries are proud to boast that our CEO, Rocky Turner, has been appointed Chairman of the 2018 Board of NCCER Trustees. LPR’s continued commitment to a cutting-edge apprentice program for our ironworkers, as well as other trades, facilitates our continued commitment to being both an NCCER Assessment Center and a Training Center. Currently we have apprentices in all levels of the program and assigned mentors, journeyman and above, to answer their content questions, serve as proctors and instructors, and provide the hands-on site-based training we know is most effective for our craft workers. Looking to partner closely with local high schools, Front Range Community College and other community programs supporting the craft trades, we hope to develop a ‘grow our own’ program utilizing a strong NCCER curriculum, coupled with training provided by some of the most skilled ironworkers in the industry.

ed to Safety

ed to Safety